Essential DTF Transfer Tips: Stop Wasting DTF Transfers

Master DTF Transfers: 5 Pro Tips

DTF Transfer Tips are the key to achieving consistent, professional-quality results with every press. Elevate your DTF crafting with these expert tips and proven frameworks designed to eliminate common issues like ghosting, peeling, and wasted transfer sheets.

Hey, T-shirt titans and crafting connoisseurs! If you’re serious about elevating your Direct-to-Film (DTF) transfer game, you know the challenges are real: ghosting, premature peeling, and the sheer frustration of a wasted transfer sheet. Achieving professional-grade results consistently requires more than just good equipment; it demands precision and proven techniques.

This guide isn’t just a collection of quick fixes. We’re diving deep into 5 high-value, actionable frameworks designed to optimize your DTF transfer process, ensuring every press counts and your finished products boast unmatched durability and aesthetic appeal. Get ready to transform your crafting workflow and maximize your profitability.

These DTF Transfer Tips help eliminate common pressing mistakes and improve consistency.

1. DTF Transfer Tips for Perfect Cold Peel Timing: The “Cold Peel” Timing Calibration Guide

The Problem: One of the most common pitfalls in DTF transfer application is improper cold peel timing. Peeling too soon or too late leads to inconsistent adhesion, unsightly ghosting, or even partial transfer failure. While DTF typically requires a cold peel, the critical question is: how cold is truly optimal for a perfect finish?

The Solution: The “3-Step Chill Check” Framework for Perfect Peeling.

- Expert Tip: The ideal temperature for a clean, cold peel is consistently below 80°F (27°C). This ensures the adhesive has fully set and bonded with the fabric fibers.

- The Framework:

- The Wait Time Test: After the initial heat press, lift the platen and allow the garment to cool. Wait exactly 30 seconds, then attempt a small, gentle corner peel. If you encounter resistance, stretching, or any sign of incomplete adhesion, wait another 30 seconds. Document your minimum effective wait time for your specific heat press, room temperature, and garment type (e.g., 60-90 seconds).

- The Surface Temperature Confirmation: Eliminate guesswork by using an inexpensive yet highly effective infrared thermometer. Point it directly at the DTF film. Do not attempt to peel until the thermometer reads below 80°F (27°C). This scientific approach guarantees optimal adhesive curing, regardless of ambient conditions.

Pro Tip for DTF Crafters: Invest in an IR thermometer to precisely guarantee your cold peel temperature is below 80°F, ensuring professional, consistent results every single time.

Professional printers rely on DTF Transfer Tips to achieve flawless adhesion every time.

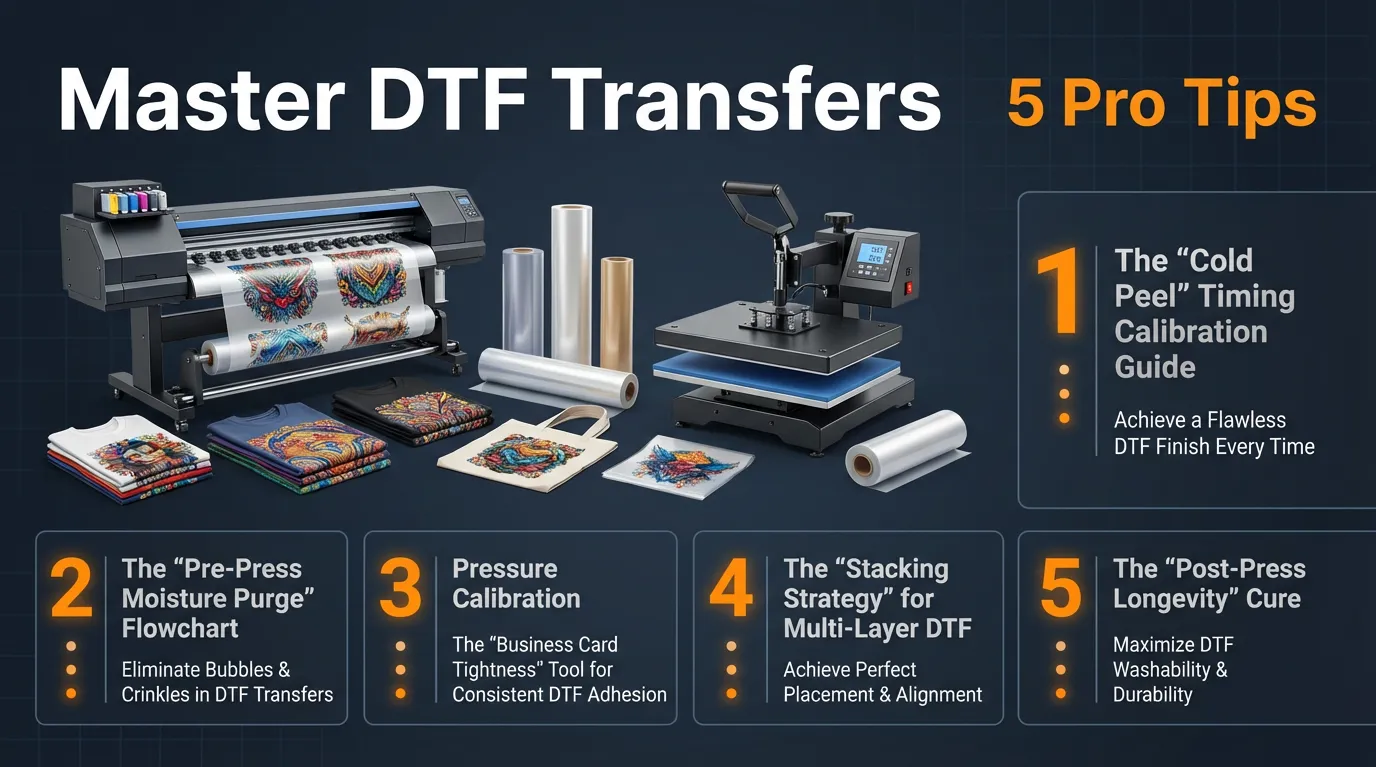

2. DTF Transfer Tips to Eliminate Moisture, Bubbles, and Crinkles: The “Pre-Press Moisture Purge” Flowchart

The Problem: Even seemingly dry garments, especially new ones, harbor microscopic moisture. During the intense heat of the press, this moisture rapidly converts to steam, creating tiny bubbles, unwanted texture issues, and significantly compromising the long-term adhesion and durability of your DTF transfer. This often leads to premature peeling and customer dissatisfaction.

The Solution: The 10-Second Moisture Purge Flowchart for Flawless Garment Prep.

- Is it a Cotton/Poly Blend or Synthetic Fabric?

- Yes: Place the blank garment on your heat press platen. Press it at your final transfer application temperature for a full 10 seconds with medium-firm pressure. This crucial step effectively purges all hidden moisture.

- No (100% Cotton/Linen): For natural fibers like 100% cotton or linen, which typically hold less moisture, a 5-second pre-press is usually sufficient.

- The Lint Roll Lockdown: Immediately after the moisture purge, while the garment is still warm on the platen, use a fresh, high-quality lint roller across the entire surface where the DTF will be applied. The heat causes tiny fabric fibers to stand up, and this step meticulously removes them, preventing any interference with the transfer’s adhesion.

- The Press-Ready Check: Lay your DTF film down immediately after lint rolling. The garment should feel warm and perfectly dry to the touch, creating an optimal surface for transfer application.

Pro Tip for DTF Crafters: Make pre-pressing a non-negotiable step for EVERY garment. A 5-10 second purge followed by a lint roll ensures a moisture-free, fiber-free surface for superior DTF adhesion.

Following proven DTF Transfer Tips reduces waste and improves production efficiency.

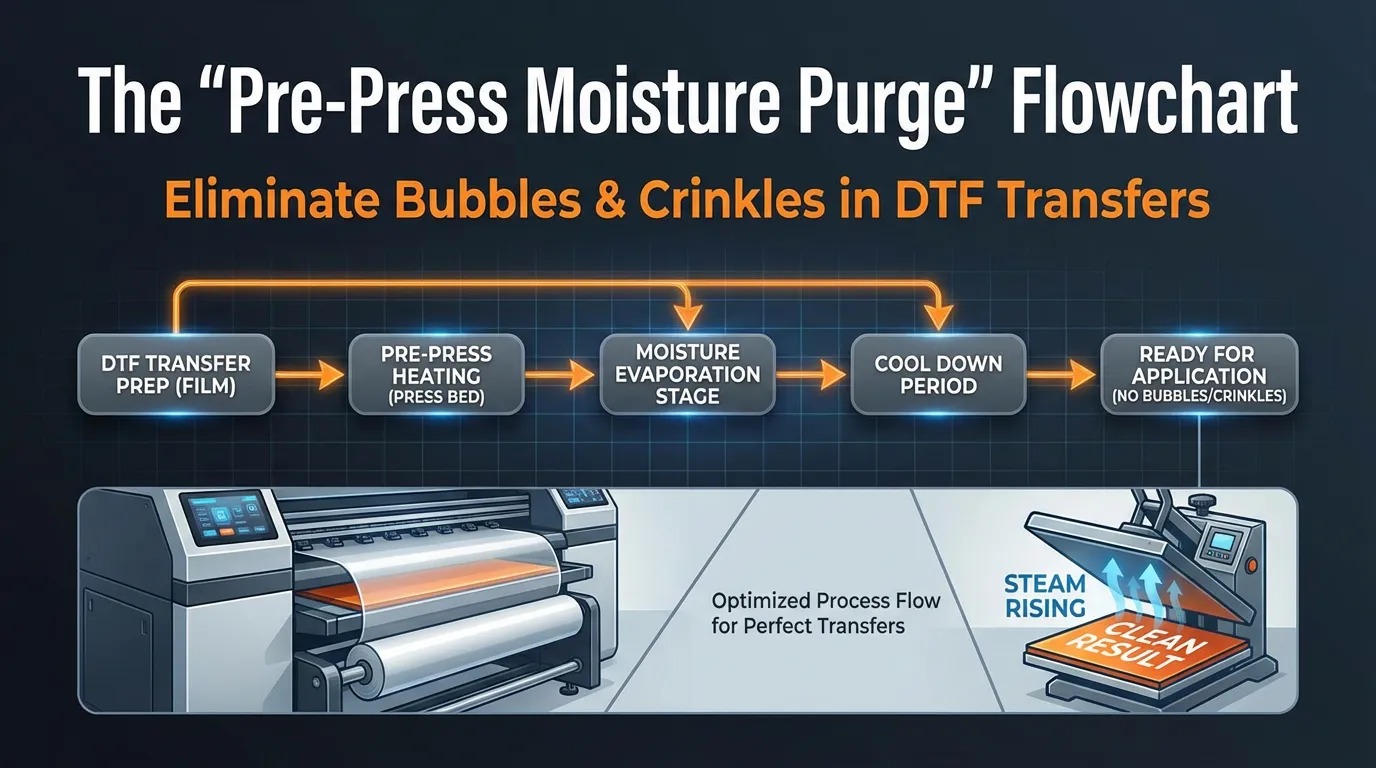

3. DTF Transfer Tips for Accurate Pressure Calibration: The “Business Card Tightness” Tool for Consistent DTF Adhesion

The Problem: Achieving the correct pressure is paramount for successful DTF transfers, yet “firm pressure” is often subjective and varies wildly between different manual heat presses. Insufficient pressure leads to uneven transfer adhesion and patchy results, while excessive pressure can squish the adhesive, causing bleed-out and an undesirable finish.

The Solution: Utilize a Standard Business Card as Your Precision Pressure Gauge.

- Expert Tip: Inconsistent or incorrect pressure is arguably the most common culprit behind spotty DTF adherence and poor washability.

- The Tool/Framework:

- Take a standard business card (or a piece of sturdy cardstock) and place it precisely at the edge of your heat press platen.

- Clamp your heat press down using the normal locking force you would apply for a DTF transfer (avoiding extreme, unnatural force).

- Attempt to slide the business card out from under the clamped press.

- Optimal Pressure Indication: You should be able to tug the card, but it should feel like you are exerting significant force, almost as if you are ripping the card in half to remove it. If the card slides out easily with minimal effort, your pressure is too light and needs to be increased. If the card is completely locked and tears instantly upon the slightest tug, your pressure is likely too heavy and should be slightly decreased.

Pro Tip for DTF Crafters: Implement the “Business Card Tightness” test (tug hard, feel like ripping) to accurately set and verify firm, consistent, and even pressure across your heat press platen.

Using the right DTF Transfer Tips is what separates hobby-level results from professional production. When pressure, temperature, peeling, and curing are all controlled properly, DTF Transfer Tips ensure your designs stay vibrant, flexible, and durable even after repeated washing.

These DTF Transfer Tips are essential for long-term durability and wash resistance.

4. DTF Transfer Tips for Multi-Layer Placement and Alignment: The “Stacking Strategy” for Multi-Layer DTF

The Problem: Applying multiple DTF transfers to a single garment—such as a large back design combined with a small chest logo, or intricate layered graphics—frequently results in crooked, misaligned, or off-center prints. This can significantly detract from the professional appearance of your finished product.

The Solution: The Painter’s Tape & Ruler Stacking Framework for Precision Placement.

- The Center Line: Begin by folding your garment vertically in half. Give the central crease a quick, light 2-second press with your heat press (avoid over-creasing, which can leave a permanent mark). This temporary crease serves as your infallible vertical alignment guide.

- The Temporary Hinge: Carefully position your first transfer (typically the largest or main design) perfectly centered on the garment, using your newly created center crease as a reference. Once satisfied with the placement, secure the top edge of the DTF film to the shirt with two pieces of low-tack painter’s tape, creating a stable “hinge.”

- The Ruler Offset: For your subsequent transfers (e.g., a chest logo, sleeve design, or additional graphic), utilize a precise ruler. Measure the exact desired distance down from the collar (a common starting point is 3 fingers or 3 inches) and horizontally from your established center crease. This ensures consistent and symmetrical placement across all elements.

- The Final Press: If all transfers fit comfortably under your heat press platen, you can apply them simultaneously. Otherwise, press them sequentially. For each section, always apply the same “3-Step Chill Check” framework (as detailed in Idea 1) for optimal cooling and peeling.

Pro Tip for DTF Crafters: Leverage a temporary center crease and a painter’s tape hinge for guaranteed straight and perfectly aligned DTF transfer placement every single time, even with complex multi-layer designs.

Mastering DTF Transfer Tips ensures every garment meets professional standards.

5. DTF Transfer Tips to Maximize Washability and Durability: The “Post-Press Longevity” Cure

The Problem: Many crafters believe the process is complete after the initial press and cold peel. However, the DTF adhesive isn’t truly “cured” into the garment fibers at this stage. Skipping the crucial post-press step often leads to premature cracking, fading, or peeling after the first few washes, significantly reducing the lifespan and perceived quality of your DTF products.

The Solution: The 5-Second Secondary Seal for Enhanced DTF Durability.

- Expert Tip: Never, under any circumstances, skip the second press! This final step is what truly cures the adhesive, embedding it deeply and permanently into the garment’s fabric fibers.

- The Framework:

- The Perfect Peel: Ensure you have completed your cold peel flawlessly, following the guidelines in Idea 1.

- The Protective Cover: IMMEDIATELY after peeling, cover the entire exposed DTF design area with a high-quality PTFE sheet (Teflon) or a silicone parchment sheet. Crucially, NEVER press the exposed DTF design directly without a cover sheet, as this can damage the print and your platen.

- The Final Seal: Press the garment again for a precise 5 seconds. Use the exact same temperature and same pressure settings as your initial DTF application press. This secondary heat application fully activates and cures the adhesive.

Pro Tip for DTF Crafters: Always follow the cold peel with a 5-second second press, utilizing a PTFE or silicone parchment sheet, to permanently seal the DTF into the fabric and maximize washability.

Advanced DTF Transfer Tips allow crafters to achieve repeatable, high-quality results.

Elevate Your DTF Crafting to Professional Heights

By meticulously implementing these 5 expert DTF transfer tips, you’re not just improving your technique; you’re investing in the quality, durability, and professional reputation of your crafting business. From precise cold peels to perfect pressure and post-press curing, each step is a building block towards flawless results that will impress your clients and stand the test of time.

Stop wasting valuable transfers and start producing garments that truly shine. Master these frameworks, and watch your DTF crafting reach new levels of excellence and efficiency.

Applying these DTF Transfer Tips prevents peeling, cracking, and ghosting.

By following these expert DTF Transfer Tips, you’re not just improving your workflow — you’re elevating the quality, durability, and consistency of every product you create. These DTF Transfer Tips help you avoid costly mistakes, reduce wasted transfers, and deliver results your customers will trust.