DTF vs. Screen Printing: The Ultimate Guide to Choosing the Right Method

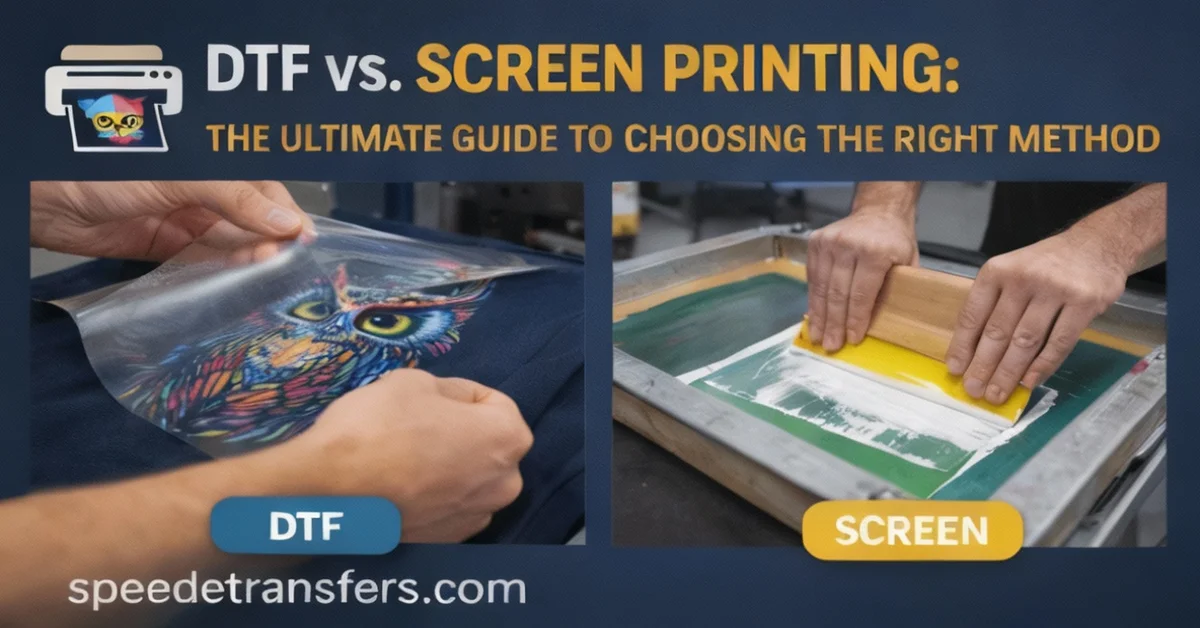

DTF vs. Screen Printing: Key Differences You Should Know

DTF vs. Screen Printing is one of the most important comparisons in custom apparel printing today. When choosing between DTF vs. Screen Printing, the decision directly affects print quality, durability, cost, and production flexibility.

Understanding DTF vs. Screen Printing helps designers, entrepreneurs, and businesses select the best printing method for their specific needs. Whether you are producing small custom batches or large-scale merchandise, knowing the strengths and limitations of DTF vs. Screen Printing ensures better results and higher return on investment.

At SpeedETransfers, we specialize in both DTF and screen printing, guiding customers through the DTF vs. Screen Printing decision based on fabric type, order size, design complexity, and budget. This complete guide to DTF vs. Screen Printing will help you confidently choose the right solution for your next project.

DTF vs. Screen Printing for Quality, Cost, and Durability

Choosing between DTF vs. Screen Printing requires evaluating print quality, wash resistance, and long-term value. For small batches, DTF vs. Screen Printing often favors DTF, while large-scale orders benefit from screen printing’s durability and lower per-unit cost.

1. Introduction: Why Choosing the Right Printing Method Matters

Selecting the right printing method is a critical step for any project. Whether you’re producing a small batch of custom T-shirts, launching a new apparel line, or designing promotional merchandise for your Austin based business, your choice between DTF printing and screen printing will impact:

- Print quality clarity, sharpness, and color vibrancy

- Durability how long the print lasts and survives washes

- Production efficiency time and workflow requirements

- Cost-effectiveness setup costs, material costs, and ROI

- Fabric compatibility whether your designs work on cotton, polyester, blends, or specialty fabrics

Making the wrong choice can lead to wasted resources, unsatisfactory prints, and lost revenue. This guide will ensure you understand the technical, artistic, and business aspects of each method, helping you make an informed choice.

2. The History and Evolution of Printing Techniques

Printing has a rich history that has evolved significantly over the centuries. Understanding this history helps appreciate the strengths and limitations of each method.

2.1 Early Printing Methods

- Block Printing: One of the earliest printing methods, dating back thousands of years. Designs were carved into wood, pressed into ink, and stamped onto fabric. This method was labor-intensive and limited to repetitive patterns.

- Stencil Techniques: Used in ancient China and the Middle East to apply designs onto textiles. These methods influenced modern screen printing by introducing the concept of selective ink application.

2.2 Modern Screen Printing

- Early 20th Century: Screen printing evolved as an industrial method for mass-producing apparel and promotional products.

- Technique: Ink is forced through a mesh stencil onto the fabric, creating bold, vibrant, and long lasting designs.

- Popularity: Screen printing became the go to method for bulk orders and solid color designs due to its durability and cost efficiency for large runs.

2.3 The Digital Revolution and Emergence of DTF

- Late 20th to Early 21st Century: Digital printing technologies emerged, allowing high-resolution, full color designs to be printed with minimal setup.

- Direct-to-Film (DTF) Printing: Developed to meet the demand for small batches, complex designs, and multi-color artwork. DTF uses digital printers, PET film, adhesive powders, and heat transfer to create soft, flexible, and detailed prints.

By combining digital precision with versatile material compatibility, DTF printing revolutionized small batch custom printing, complementing traditional screen printing for bulk orders.

3. Understanding Direct-to-Film (DTF) Printing

3.1 Origins and Development

Direct-to-Film printing is a digital printing method designed for high detail, multi color designs. It allows artists and businesses to produce vibrant, soft, and flexible prints on a wide variety of fabrics, making it ideal for modern custom apparel businesses like speedEtransfers.

Unlike heat transfers or vinyl, DTF prints adhere directly to fabrics using heat-activated adhesive powder, producing long lasting results without stiffness.

3.2 Step-by-Step DTF Workflow

Step 1: Artwork Creation

- Use Adobe Illustrator, Photoshop, or CorelDRAW to create high resolution artwork.

- Ensure designs are mirrored for transfer if needed.

- Save in transparent formats like PNG or PSD to maintain background transparency.

- Use CMYK color profiles for accurate color reproduction.

Step 2: Printing on PET Film

- Print designs on PET transfer film using DTF printers.

- Use water-based or pigment inks for vibrant colors.

- Dry partially before adhesive application to avoid smudging.

Step 3: Applying Adhesive Powder

- Sprinkle hot melt adhesive powder onto printed areas.

- Remove excess powder using a sifter or a gentle air blower.

- Powder ensures the ink adheres to the fabric during heat transfer.

Step 4: Curing the Adhesive

- Pass the printed film through a curing oven or heat tunnel.

- Heat melts the powder, creating a tacky surface ready for transfer.

Step 5: Heat Transfer

- Position the film on the fabric using a heat press.

- Apply recommended temperature, pressure, and time for the specific fabric.

- Peel the film according to adhesive type (hot peel or cold peel).

Step 6: Quality Inspection

- Inspect prints for color accuracy, detail, and adhesion.

- Ensure there are no bubbles, misalignments, or incomplete transfers.

3.3 Advantages of DTF Printing

- High resolution, photo realistic prints with gradients.

- Works on a wide range of fabrics: cotton, polyester, blends, synthetics.

- Soft, flexible hand feel.

- Ideal for small batches, custom orders, and on-demand printing.

- Minimal setup costs compared to screen printing.

3.4 Limitations

- Slightly less durable than screen printing for frequent heavy washes.

- Requires specialized DTF printers and consumables.

- Higher per unit costs for very large orders.

4. Understanding Screen Printing

4.1 Origins and Development

Screen printing has been a trusted method for decades due to its bold and durable prints. Its origins trace back to early stencil and mesh techniques, refined into a standard industrial printing process in the 20th century.

4.2 Step-by-Step Screen Printing Workflow

Step 1: Artwork Preparation

- Separate the design by color for multi-color prints.

- Ensure high-resolution files for precise stenciling.

Step 2: Screen Preparation

- Coat mesh screens with photo sensitive emulsion.

- Use UV light to expose designs onto screens, creating stencils.

Step 3: Printing

- Apply ink to screens, forcing it through the mesh with a squeegee.

- Print each color sequentially for multi color designs.

Step 4: Curing

- Heat cure prints to ensure durability and wash resistance.

Step 5: Quality Check

- Inspect prints for alignment, color consistency, and adhesion.

4.3 Advantages of Screen Printing

- Extremely durable and long-lasting prints.

- Vibrant colors, excellent for dark fabrics.

- Cost-effective for bulk orders.

4.4 Limitations

- Not ideal for intricate, multi-color designs.

- High setup cost for small orders.

- Slower for complex multi-color prints.

5. Technical Comparison: DTF vs Screen Printing

When comparing DTF printing Austin and screen printing services, technical aspects play a crucial role in determining the right method for your project. Here’s an in depth look at key factors.

5.1 Print Quality and Resolution

DTF Printing:

- Achieves up to 1440 dpi, producing sharp, intricate designs.

- Ideal for photographic images, small text, and gradients.

- Layering of colors is precise, allowing smooth transitions without halos or misalignment.

Screen Printing:

- Depends on the mesh count; fine details can blur if the mesh is coarse.

- Excellent for bold, solid color designs, but less suitable for complex gradients.

- Multi-color designs require multiple screens, increasing alignment complexity.

Verdict: DTF excels in high detail and photorealistic designs, while screen printing is preferred for bold, simple artwork.

5.2 Color Accuracy and Vibrancy

DTF Printing:

- Uses CMYK or full color ink sets, allowing seamless gradient reproduction.

- Works well on light and dark fabrics, with a white underbase for opacity.

- Vibrancy is consistent across multiple fabric types.

Screen Printing:

- Uses pigment based inks; colors are vibrant and bold, especially on dark fabrics.

- Gradients require halftone techniques, which can slightly reduce smoothness.

- Consistent color reproduction is reliable for bulk orders.

Verdict: For complex color transitions, DTF is superior; for solid, vibrant colors, screen printing excels.

5.3 Durability and Washability

DTF Printing:

- Prints are flexible and adhere well to various fabrics.

- Proper heat curing ensures moderate to high durability.

- Frequent washing may slightly reduce vibrancy over time.

Screen Printing:

- Extremely durable; colors and patterns can survive hundreds of washes.

- Less prone to cracking or fading, ideal for long term apparel.

Verdict: Screen printing is the more durable choice for heavy use garments.

5.4 Fabric Compatibility

DTF Printing:

- Works on cotton, polyester, blends, synthetics, silk, leather, and more.

- Versatility makes it ideal for custom projects with diverse fabric types.

Screen Printing:

- Best suited for cotton heavy fabrics.

- Polyester and synthetics require specialized inks and may have reduced durability.

Verdict: DTF is the most versatile option for multiple fabrics.

5.5 Production Speed and Scalability

DTF Printing:

- Minimal setup; perfect for small batches or on-demand orders.

- Fast turnaround for custom designs.

Screen Printing:

- Setup takes longer due to screen preparation

- Efficient for bulk orders, as per-unit cost decreases with volume.

Verdict: DTF is ideal for quick, small orders, while screen printing is optimized for high volume production.

5.6 Environmental Considerations

- DTF: Uses water based inks; PET film is recyclable.

- Screen Printing: Water based and eco friendly inks available, but traditional plastisol can be less environmentally friendly.

- Both methods can be made sustainable with proper practices.

6. Detailed Cost Analysis and ROI

Cost is a critical factor in deciding which method to use.

6.1 Material Costs

DTF:

- PET film, inks, adhesive powder, and printer maintenance.

- Costs remain reasonable for small to medium batches.

Screen Printing:

- Mesh screens, squeegees, emulsion, and inks.

- High setup cost for multi color designs.

6.2 Setup Costs

- DTF requires minimal setup.

- Screen printing setup is more expensive, especially for multi color artwork.

6.3 Per-Unit Cost Analysis

- Small batch (1–50 units): DTF is more economical.

- Large batch (100+ units): Screen printing reduces per unit cost due to amortized setup.

6.4 Return on Investment

- DTF: Minimizes inventory waste and supports on demand customization.

- Screen Printing: Maximizes ROI for bulk orders, reducing cost per unit while delivering long lasting prints.

7. Fabric Compatibility and Design Considerations

7.1 Fabric Types

- DTF works on cotton, polyester, poly cotton blends, nylon, silk, and leather.

- Screen printing is optimized for cotton rich fabrics, with special inks needed for synthetics.

7.2 Design Preparation

- High resolution files (300 dpi minimum).

- Transparent PNG or PSD for DTF; vector files (AI/EPS) for screen printing.

7.3 Color Separation and Gradients

- DTF supports gradients and soft transitions easily.

- Screen printing requires halftones and careful color separation.

7.4 Layer Management and Optimization

- Organize layers clearly to avoid misalignment.

- Simplify complex designs for screen printing to reduce setup time and cost.

8. Step-by-Step Guide to Choosing the Right Method

- Determine order size: Small = DTF; Large = Screen Printing.

- Assess design complexity: Intricate = DTF; Bold = Screen Printing.

- Evaluate fabric type: Mixed fabrics = DTF; Cotton-heavy = Screen Printing.

- Decide on durability requirements: Heavy wash = Screen Printing.

- Analyze budget and turnaround: Small runs = DTF; Bulk = Screen Printing.

- Factor in production speed and delivery deadlines.

9. Maintaining Prints for Longevity

- Wash inside out in cold water.

- Use mild detergents, avoid bleach.

- Iron inside out, low heat.

- Air dry or tumble dry on low heat.

- Proper care can extend the lifespan of DTF and screen prints significantly.

10. Common Myths and Misconceptions

- DTF fades quickly: False if properly cured.

- Screen printing handles all designs: False for intricate, photographic images.

- DTF is always expensive: False; economical for small, custom orders.

- Screen printing is outdated: False; remains the standard for bulk, durable prints.

11. Future Trends in Printing Technology

- Eco-friendly inks and sustainable materials.

- Hybrid printing methods combining DTF and screen printing.

- Automation and AI in design placement and printing workflows.

- Increasing popularity of on demand custom apparel.

- Advanced resolution and durability improvements.

12. Local Austin Market Insights and Practical Tips

- Austin has a booming custom apparel market, with demand for small batch, unique designs.

- DTF printing is ideal for startups and boutique designers seeking flexibility.

- Screen printing remains cost-effective for corporate orders and event merchandise.

- Partnering with a trusted service like speedEtransfers ensures professional results and faster delivery.

13. Case Scenarios and Examples

- Startup Apparel Line: DTF allows customization, small runs, and quick turnaround.

- Corporate Event Merchandise: Screen printing reduces per unit costs for bulk orders.

- Mixed Fabric Product Line: DTF handles cotton, polyester, and specialty fabrics seamlessly.

- Complex Multi-Color Artwork: DTF reproduces gradients and photorealistic images effectively.

14. FAQs and Troubleshooting

Q1: Can DTF prints be washed like screen prints?

- Yes, with proper curing and care.

Q2: Can screen printing produce photographic images?

- Yes, but requires halftones and multiple screens; not ideal for complex gradients.

Q3: Which method is best for small custom orders?

- DTF is ideal due to minimal setup and on demand production.

Q4: Which method is more durable long-term?

- Screen printing is more durable for garments that will be washed frequently.

Q5: Can DTF be used on non-cotton fabrics?

- Yes, it works on polyester, blends, synthetics, silk, and leather.

Quick Summary: DTF vs. Screen Printing at a Glance

Choosing between DTF vs. Screen Printing depends on how you balance quality, cost, and durability. Here is a simple breakdown of DTF vs. Screen Printing to help you decide faster:

- DTF vs. Screen Printing for small orders: DTF wins due to minimal setup and fast turnaround.

- DTF vs. Screen Printing for bulk orders: Screen printing is more cost-effective and durable.

- DTF vs. Screen Printing for complex designs: DTF handles gradients and details better.

- DTF vs. Screen Printing for bold logos: Screen printing delivers stronger solid colors.

- DTF vs. Screen Printing for mixed fabrics: DTF works on cotton, polyester, blends, and synthetics.

- DTF vs. Screen Printing for long-term wear: Screen printing offers superior durability.

When comparing DTF vs. Screen Printing, there is no one-size-fits-all solution. The best choice depends on your design, fabric, budget, and production goals. That’s why understanding DTF vs. Screen Printing is essential before placing your next order.

15. Conclusion

| Feature | DTF Printing | Screen Printing |

| Resolution | High (1440 dpi) | Medium high (mesh-dependent) |

| Color Accuracy | Excellent for gradients | Vibrant for solids |

| Durability | Moderate to high | Extremely high |

| Fabric Compatibility | Versatile (cotton, polyester, blends) | Best on cotton-heavy fabrics |

| Production Speed | Fast for small runs | Efficient for large runs |

| Environmental | Water-based inks, recyclable films | Water-based options, plastisol less eco friendly |

Both DTF printing Austin and screen printing services have unique advantages. Your choice should consider:

- Order size

- Design complexity

- Fabric type

- Durability requirements

- Budget and turnaround

At speedEtransfers, we provide expert guidance, professional equipment, and high quality printing services to bring your custom designs to life. Whether you need intricate DTF prints or durable screen-printed bulk orders, we deliver results that exceed expectations. Contact speedEtransfers today to discuss your next project and explore our DTF printing and screen printing services in Austin. Bring your designs to life with professional, high-quality custom prints!

FOLLOW US ON: Facebook