Can You Print DTF with a Sublimation Printer? DTF vs Sublimation

Printing technologies have come a long way, offering a range of methods to transfer designs onto various materials. Two popular methods are DTF (Direct-to-Film) printing and sublimation printing. Have you ever wondered if you could print DTF with a sublimation printer?

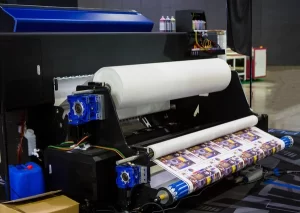

DTF printing is a process where designs are printed directly onto a special film, which is then transferred to fabric using a heat press. This method is known for its versatility and ability to print on a variety of materials, including cotton, polyester, and blends.

Sublimation printing, on the other hand, involves printing designs onto special transfer paper using sublimation inks. The design is then transferred to a substrate, typically polyester or polymer-coated items, through a heat press. This method is renowned for producing vibrant and durable prints.

The purpose of this article is to explore whether you can use a sublimation printer for DTF printing and to compare the two methods in terms of their applications, advantages, and limitations.

Can You Print DTF with a Sublimation Printer?

The simple answer is “NO”. But you can make it yes by using some specific techniques.

To understand whether you can print DTF (Direct-to-Film) with a sublimation printer, it’s essential to look at the technical differences between these two types of printers.

Differences in Ink Composition and Requirements

- DTF Inks: DTF printers use special pigment-based inks. These inks stick to DTF film and then get transferred to fabric with a heat press. They must handle the heat and bond well with the fabric.

- Sublimation Inks: Sublimation printers use dye-based inks that turn into gas when heated. This gas goes into polyester fabrics or polymer-coated items. These inks are made to work with polyester and won’t work with other materials.

The key differences in ink composition and transfer processes mean that sublimation printers and inks are incompatible with the DTF process. Sublimation inks cannot adhere to the DTF film or the adhesive powder, and the sublimation transfer method does not work with the materials used in DTF printing.

DTF Printing vs Sublimation

What is DTF Printing?

DTF (Direct-to-Film) printing is a method where designs are printed directly onto a special film.

Materials Needed for DTF Printing

- DTF printer

- DTF inks (pigment-based)

- DTF film

- Hot-melt adhesive powder

- Heat press

- Design software

Common Uses of DTF Printing

DTF printing is commonly used for customizing apparel such as t-shirts, hoodies, and bags. It’s also used for printing on a variety of other items like caps, shoes, and even certain hard surfaces. This method is popular in the fashion and promotional products industries due to its versatility and ability to produce high-quality prints on different materials.

Advantages of DTF Printing

Versatility in Printing on Various Fabrics

DTF printing is highly versatile, allowing you to print on a wide range of fabrics, including cotton, polyester, blends, and more. This flexibility makes it ideal for customizing various textile products.

Durability of Prints

Prints produced through DTF are durable and long-lasting. The hot-melt adhesive used in the process ensures that the prints adhere strongly to the fabric, making them resistant to washing and regular wear.

Ease of Use for Small to Large Production Runs

DTF printing is suitable for both small and large production runs. Whether you need a single custom t-shirt or hundreds of items for an event, DTF can handle the job efficiently. This makes it a cost-effective option for businesses of all sizes.

Disadvantages of DTF Printing

Initial Cost of Equipment

One of the primary disadvantages of DTF printing is the initial cost of the equipment. Purchasing a DTF printer, heat press, and other necessary materials can be expensive, making it a significant investment for small businesses or hobbyists.

Complexity of the Process

The DTF printing process can be complex and requires careful handling of materials and precise control of temperature and pressure during the transfer. This complexity may require training and practice to achieve optimal results.

Need for Specific DTF Inks and Films

DTF printing requires the use of specific DTF inks and films, which can limit the availability of supplies and potentially increase costs. It’s essential to use the correct materials to ensure the quality and durability of the prints.

What is Sublimation Printing?

Sublimation printing is a way to print designs onto special paper using special inks. Then, you use a heat press to transfer the design from the paper to things like polyester fabric or items with a special coating.

When the heat press is used, the inks turn into gas and go into the fabric or coated item, making a bright and lasting print.

Materials Needed for Sublimation Printing

- Sublimation printer

- Sublimation inks (dye-based)

- Sublimation transfer paper

- Heat press

- Design software

- Polyester fabrics or polymer-coated items

Common Uses of Sublimation Printing

Sublimation printing is commonly used for customizing polyester apparel such as t-shirts, sportswear, and uniforms. It’s also popular for creating personalized items like mugs, phone cases, mouse pads, and other polymer-coated products.

This method is widely used in the promotional products industry and for producing high-quality, customized gifts.

Advantages of Sublimation Printing

High-Quality, Vibrant Prints

Sublimation printing is known for producing high-quality, vibrant prints with a wide range of colors. The dye-based inks penetrate the material, resulting in sharp and vivid images that are difficult to achieve with other printing methods.

Long-Lasting Colors

The colors in sublimation prints are long-lasting and resistant to fading. Because the ink becomes part of the fabric or coating, the prints do not crack, peel, or wash away over time, ensuring the longevity of the design.

Suitable for Polyester Fabrics and Coated Items

Sublimation printing is ideal for polyester fabrics and polymer-coated items. The process works best with these materials because the dye bonds well with polyester fibers and coated surfaces, providing a durable and high-quality finish.

Disadvantages of Sublimation Printing

Limited to Polyester and Polymer-Coated Surfaces

One of the main limitations of sublimation printing is that it can only be used on polyester fabrics and polymer-coated surfaces. This restricts the types of materials that can be printed on, making it unsuitable for cotton, nylon, and other natural fabrics.

Not Suitable for Dark Fabrics

Sublimation printing is not effective on dark fabrics. The process works best on white or light-colored substrates because the dye is transparent and does not show up well on dark backgrounds. This limits the color options for the items being printed.

Requires Special Sublimation Inks and Transfer Papers

Sublimation printing requires the use of special sublimation inks and transfer papers. These materials are specifically designed for the sublimation process and can be more expensive than regular inks and papers. Using the correct materials is essential to achieve the desired quality and durability of the prints.